Plastic cover panels support

more complex designs,

like large sizes or curved

surfaces

Requests continue to increase for large cover panels or ones with curved surfaces.

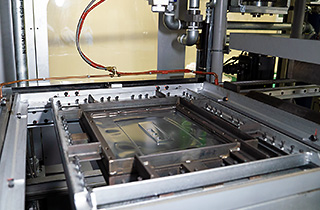

Our Film Insert Injection Molding technology can satisfy those requests.

We are improving our technology to support even more intricate shapes.